MINIVALVE® trays produced by Koch-Glitsch produce reduced entrainment and better efficiency than conventional valve and sieve tray designs.

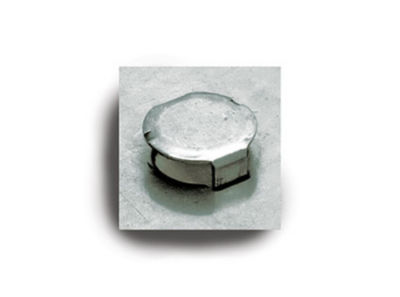

The MINIVALVE® trays produce reduced entrainment and better efficiency than conventional valve tray design and sieve trays. The improvement in capacity can exceed 13% in spray regime services with low-to-moderate weir loadings. MINIVALVE® valves exhibit a more uniform froth action on the tray deck compared to full-size valves. They are offered in both fixed (VG-0) and movable (MV-1) styles.

MINIVALVE® valves are directional with the rear leg being a little wider than the downstream front leg. This gives a slight pushing action to the liquid as vapor passes through the valves. The liquid push assists in maintaining a more uniform flow pattern on cross-flow trays with less retrograde action. It also helps offset vapor cross-flow channeling effects to a small degree.