Koch-Glitsch KY-FIBER media is a high-efficiency product specially designed for the separation of fine dispersions of one liquid phase from another.

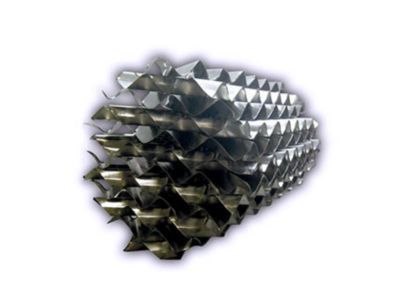

KY-FIBER media is a high-efficiency product specially designed for separation of fine dispersions of one liquid phase from another. Depending on chemical compatibility and wettability, these elements incorporate glass fiber, carbon, or plastic fiber, which is positioned between concentric screens in a metal or plastic cage.

Similar to the FLEXIFIBER® mist eliminator, these elements are installed via mounting flange onto a tube sheet contained in the separator. The liquid phases are forced to flow radially through the media, which coalesces the small droplets in the dispersed phase for separation from the continuous liquid phase.

The performance characteristics of KY-FIBER media make it a good fit for dispersions that create a hazy appearance. Typically, these dispersions are tough to separate with long settling times or conventional media. KY-FIBER media is not recommended for fouling services.