VORSOMAX® cyclonic inlet devices deliver good separation of vapor and liquid phases and decrease the momentum of feed streams entering inlet nozzles.

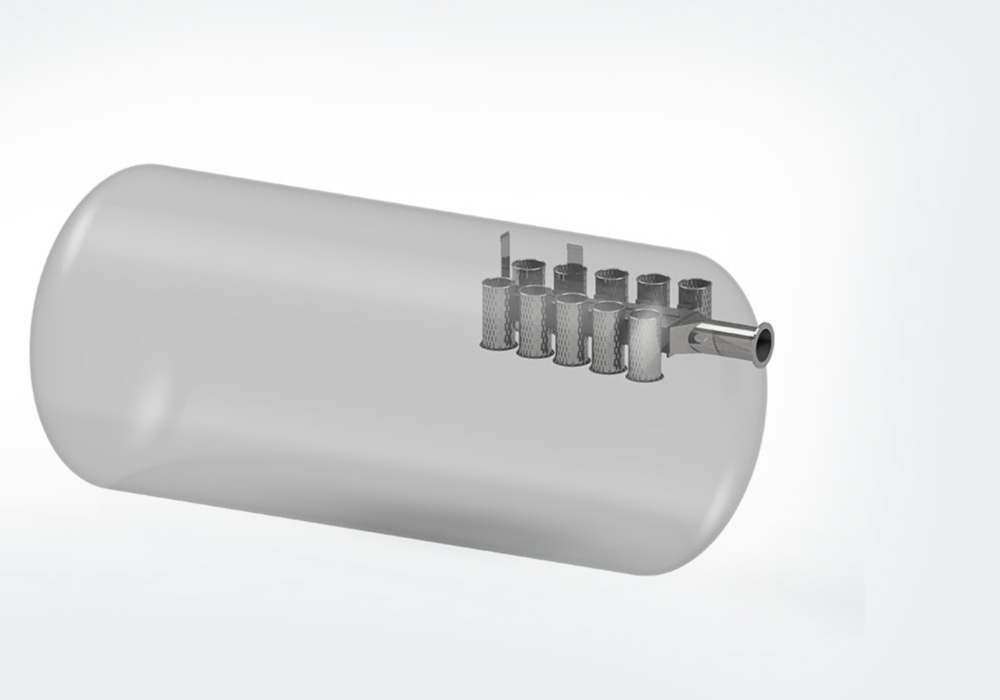

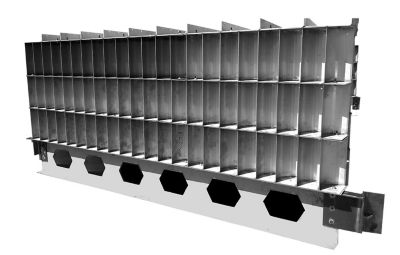

The VORSOMAX® cyclonic inlet device is a patent-pending inlet device that delivers good separation of vapor and liquid phases. It consists of a manifold and a series of separation cans, in which centrifugal force is generated to provide the vapor-liquid separation.

VORSOMAX® cyclonic inlet device decreases the momentum of the feed stream entering an inlet nozzle. This is performed in a controlled manner that allows:

- Removal of bulk liquid and some solids

- Foam breaking or suppression

- Good distribution of vapor over downstream internals

- Reduced liquid loading to downstream mist elimination equipment

- Minimization of droplet shatter, which prevents creation of additional fine entrainment

- Reduction of forces generated by vapor acting on liquid surfaces below the feed point, which prevents re-entrainment

- Lower pressure drop compared to conventional inlet cyclones

Characteristics of VORSOMAX® cyclonic inlet device

- Due to high efficiency separation of liquid from vapor, reduces liquid load to mist elimination equipment

- Prevents shear forces acting on liquid levels, which can lead to re-entrainment of previously collected liquid

- Modular construction allows for easy installation through vessel manways

- Custom engineered for vertical or horizontal vessels

Benefits

- Minimizes new vessel diameter and weight

- High gas turndown

- Ideal for debottlenecking existing separators for capacity upgrades