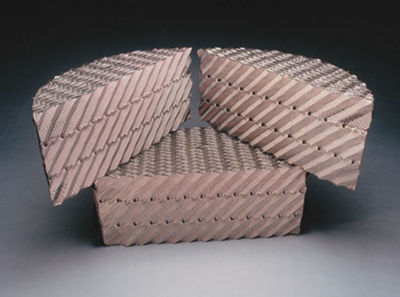

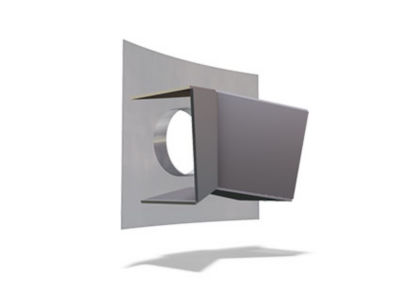

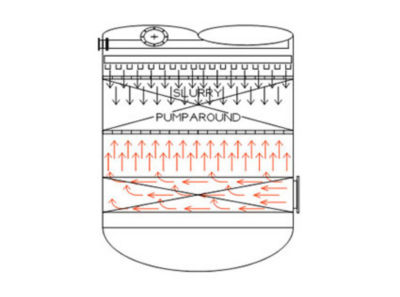

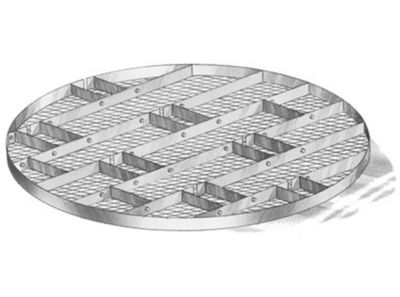

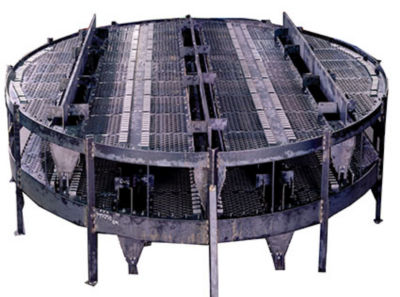

SUPERFLUX® trays from Koch-Glitsch provide increased fouling resistance, which can lead to increased run times between cleaning shutdowns.

To ensure the appropriate technologies are applied for each SUPERFLUX® tray design, Koch-Glitsch engineers work with each client to obtain the specific characteristics of fouling that must be addressed. Features suitable for the specific application are combined into a final design to produce a tray capable of longer run times between cleaning shutdowns.

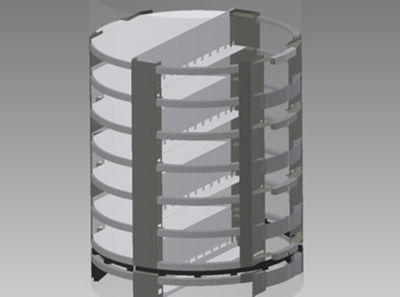

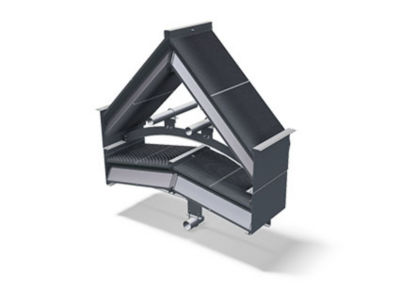

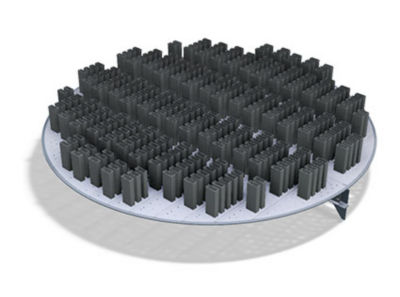

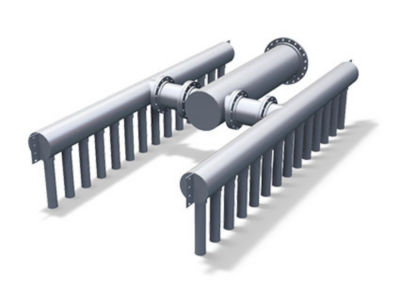

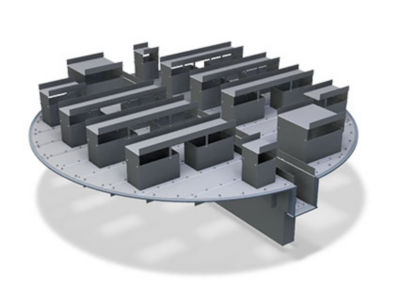

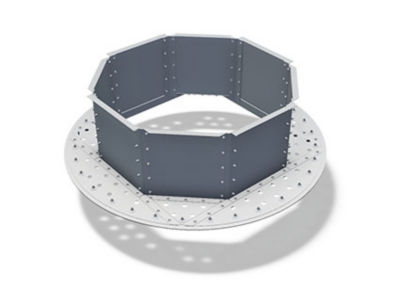

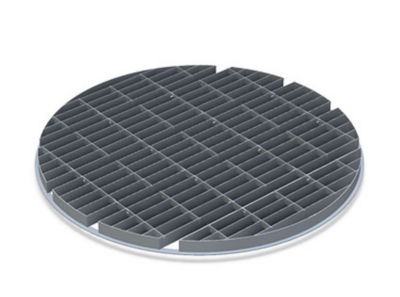

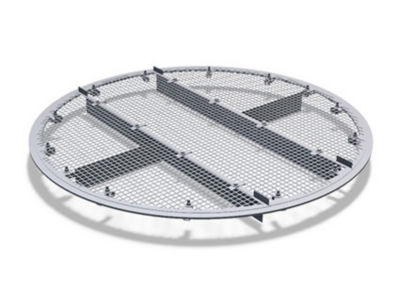

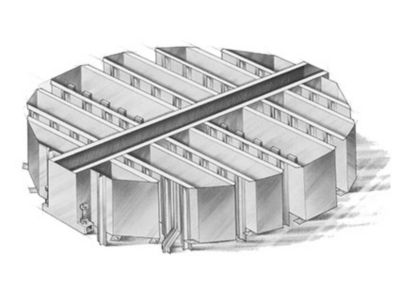

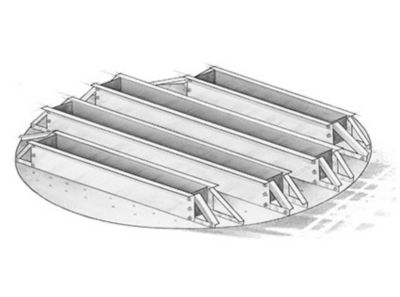

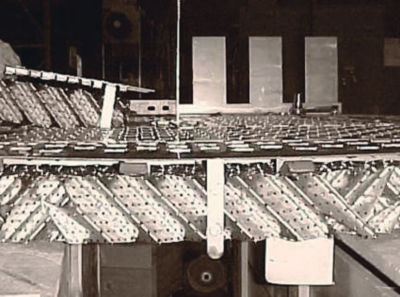

Conventional Downcomers

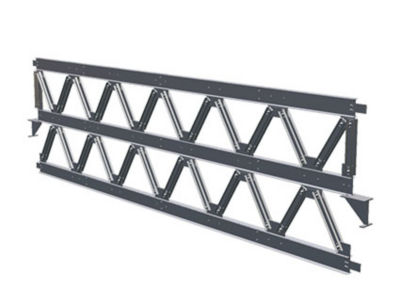

SUPERFLUX® trays with conventional downcomers use active area enhancements and may have inlet area enhancements. The straightforward design of the downcomers allows the use of standard tray construction and simplifies installation.

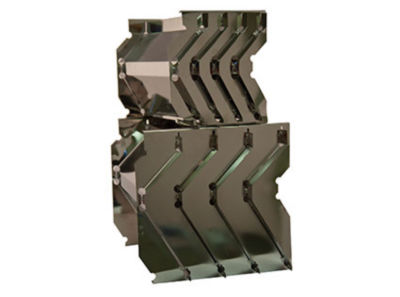

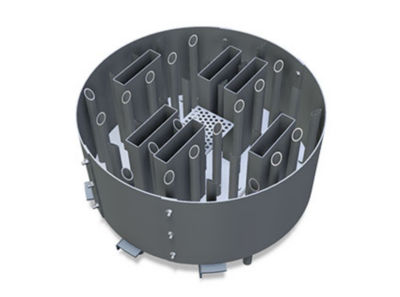

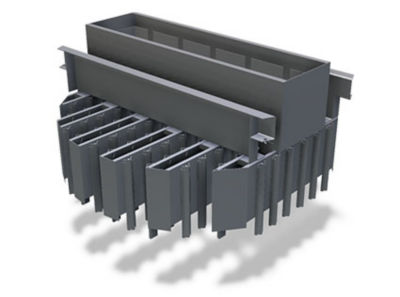

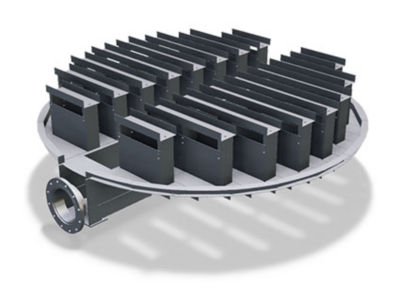

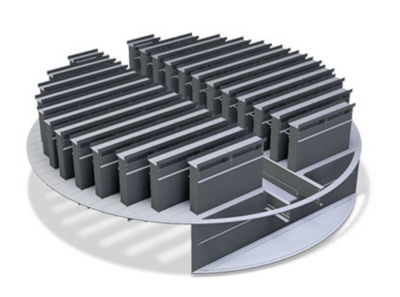

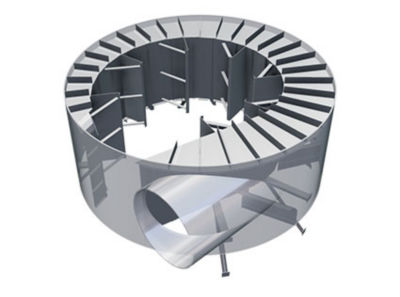

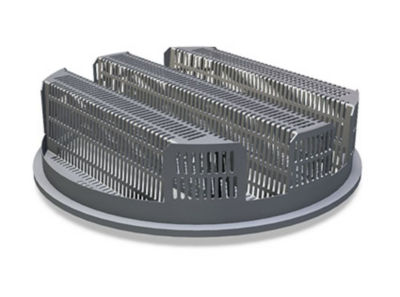

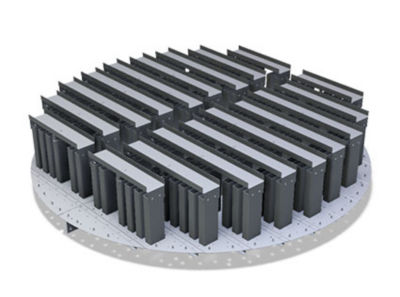

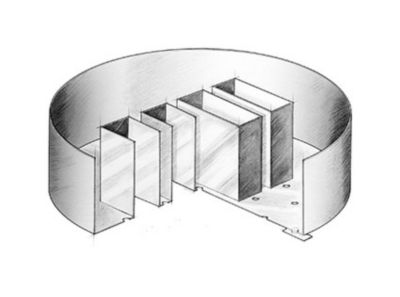

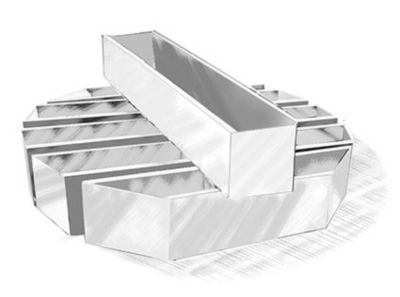

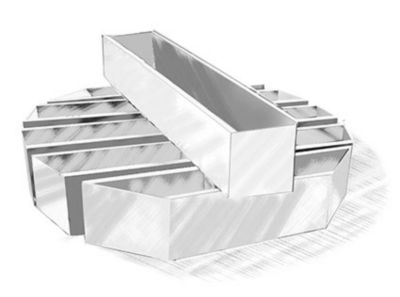

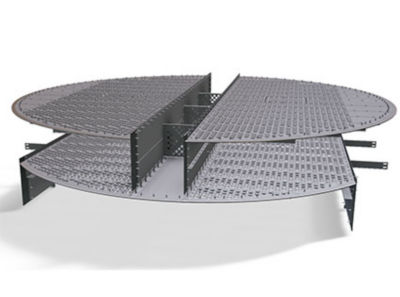

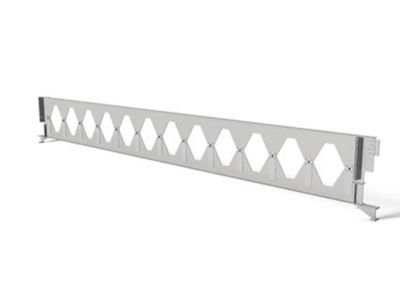

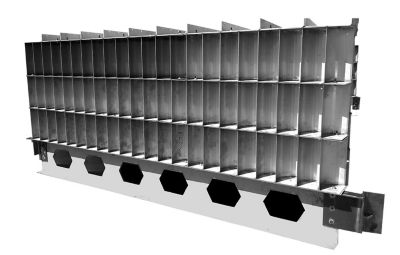

PURGE Downcomers

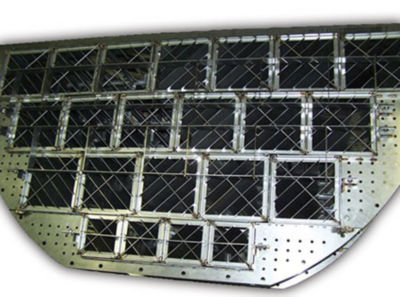

In processes where downcomer fouling is known to cause frequent shutdowns, Koch-Glitsch offers the PURGE downcomer configuration. The PURGE downcomer has proven suitable to resist fouling for such services as polymer slurry, acrylonitrile, and butadiene services.

The PURGE downcomer SUPERFLUX® trays use active area enhancements and may have inlet area enhancements. Very specific advanced downcomer technologies have been applied to the PURGE downcomer trays.

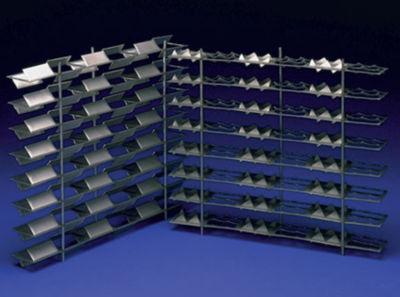

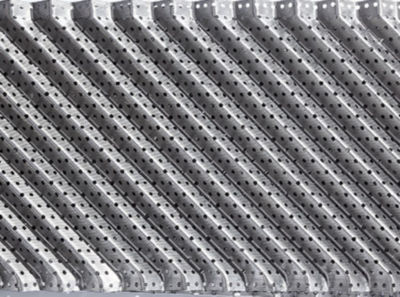

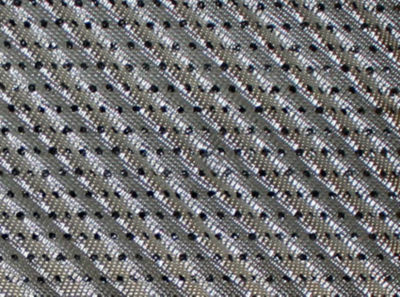

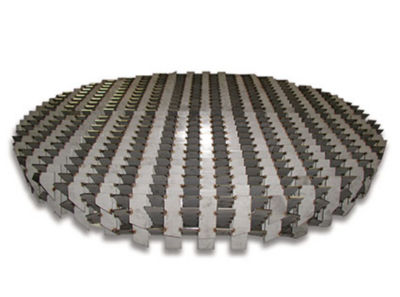

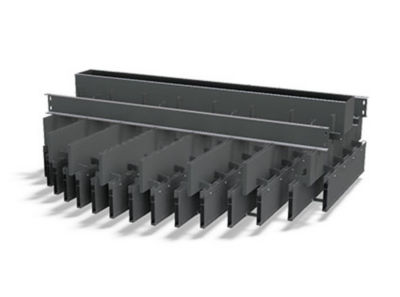

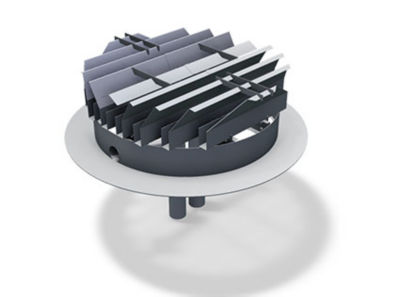

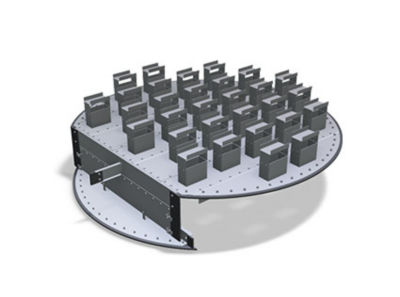

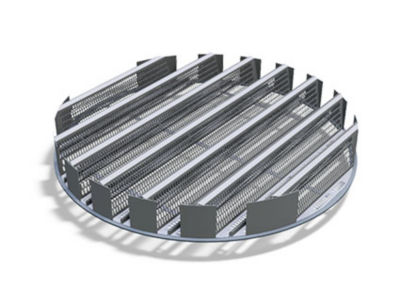

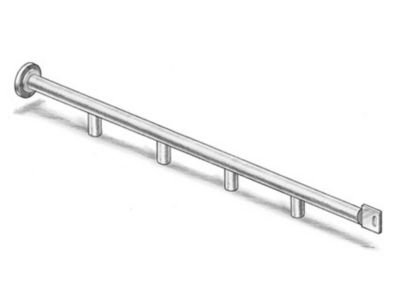

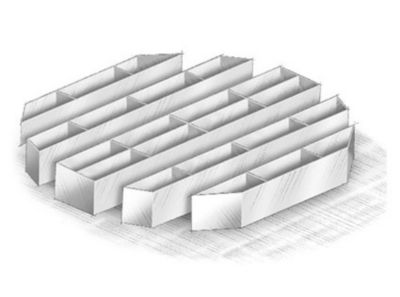

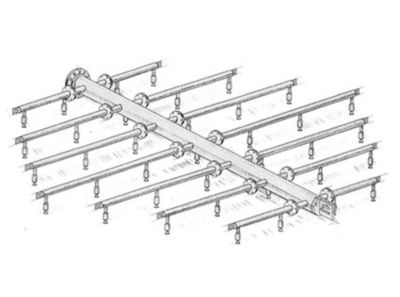

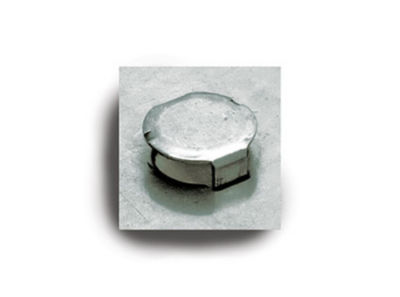

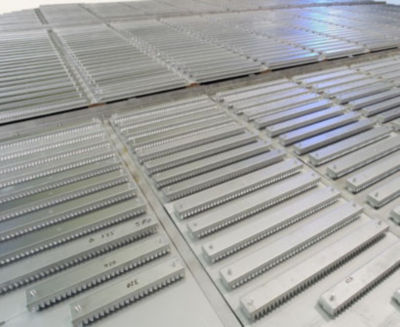

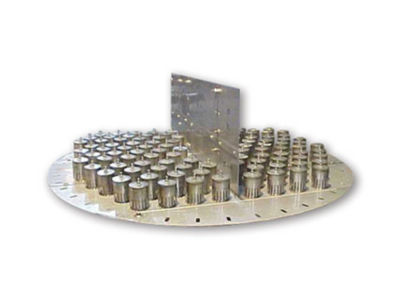

Tray valves

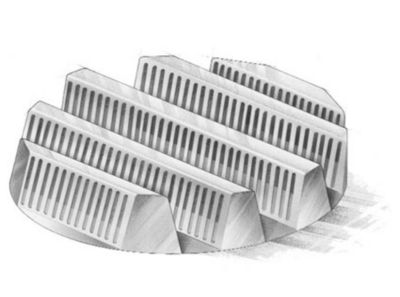

SUPERFLUX® trays provide increased fouling resistance, which can lead to increased run times. Large diameter fixed valves that are fouling resistant are a standard feature.

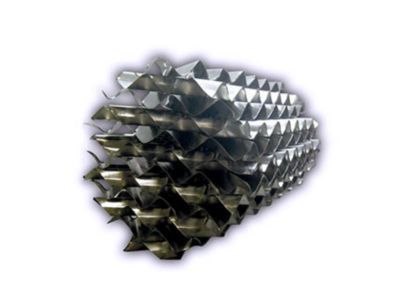

Several valve options are available that promote self-cleaning of the active areas. These valves have directional components that utilize vapor energy to provide forward-lateral push on the froth. This action is critically important to maintain proper tray activity and reduce residence time of solids on the tray deck.

Particular attention is paid to the peripheral areas of the deck where stagnation may lead to solids deposition. Directional valves are placed in this area to both increase activity as well as promote a uniform flow profile. These components combine to reduce the residence time distribution and enhance the fouling resistance of the trays.

Such a tray design is suitable for processes which are particularly prone to active area fouling, such as sour water strippers and beer strippers.